The Single Strategy To Use For Roar Solutions

The Single Strategy To Use For Roar Solutions

Blog Article

The smart Trick of Roar Solutions That Nobody is Talking About

Table of ContentsRoar Solutions Fundamentals ExplainedTop Guidelines Of Roar SolutionsExamine This Report about Roar Solutions4 Simple Techniques For Roar Solutions

The tools register is a thorough data source of devices records that includes a minimum set of areas to recognize each thing's area, technological specifications, Ex lover classification, age, and environmental data. This details is essential for tracking and taking care of the devices successfully within dangerous areas. In contrast, for routine or RBI tasting assessments, the grade will be a mix of Thorough and Close assessments. The ratio of Detailed to Shut assessments will certainly be established by the Tools Danger, which is assessed based upon ignition danger (the possibility of a resource of ignition versus the likelihood of a flammable atmosphere )and the hazardous area category( Zone 0, 1, or 2). This variation will additionally influence the resourcing demands for job preparation. Once Great deals are specified, you can develop tasting strategies based upon the sample size of each Great deal, which describes the number of random tools things to be examined. To figure out the called for sample size, two elements require to be evaluated: the size of the Great deal and the group of evaluation, which suggests the degree of initiative that should be applied( decreased, typical, or raised )to the inspection of the Lot. By integrating the classification of examination with the Whole lot dimension, you can after that develop the appropriate being rejected requirements for an example, indicating the allowed variety of malfunctioning items found within that sample. For more details on this procedure, please describe the Power Institute Standards. The IEC 60079 typical recommends that the optimum period in between inspections should not exceed 3 years. EEHA examinations will certainly additionally be performed beyond RBI campaigns as part of scheduled upkeep and tools overhauls or fixings. These examinations can be attributed toward the RBI sample dimensions within the influenced Great deals. EEHA evaluations are conducted to identify mistakes in electrical equipment. A heavy racking up system is necessary, as a single tool might have several mistakes, each with differing levels of ignition threat. If the mixed score of both inspections is less than twice the fault rating, the Great deal is considered acceptable. If the Whole lot is still thought about inappropriate, it must undertake a full inspection or validation, which may trigger more stringent assessment methods. Accepted Great deal: The reasons for any kind of faults are identified. If an usual failure setting is discovered, added devices might require inspection and fixing. Faults are identified by seriousness( Safety and security, Stability, Housekeeping ), making sure that urgent problems are examined and dealt with quickly to mitigate any type of influence on safety or procedures. The EEHA data source ought to track and tape the lifecycle of mistakes along with the restorative activities taken. Executing a durable Risk-Based Inspection( RBI )technique is important for guaranteeing compliance and safety and security in handling Electrical Devices in Hazardous Locations( EEHA). Automated Mistake Scoring and Lifecycle Administration: Easily take care of faults and track their lifecycle to improve examination accuracy. The introduction of this support for risk-based assessment better enhances Inspectivity's setting as a best-in-class option for governing conformity, as well as for any asset-centric assessment usage instance. If you want learning more, we invite you to request a demonstration and find exactly how our option can change your EEHA administration procedures.

With over one decade of consolidated Ex lover experience (IECEx/ATEX, EEHA), Saipex started to advertise the significance of proficiency of all employees associated with the Hazardous Area field in 2019. In 2021, our collaboration with IndEx and Tech Ability International (TSI) marked a milestone in the Saipex roadway to continue Ex-spouse enhancement.

An Unbiased View of Roar Solutions

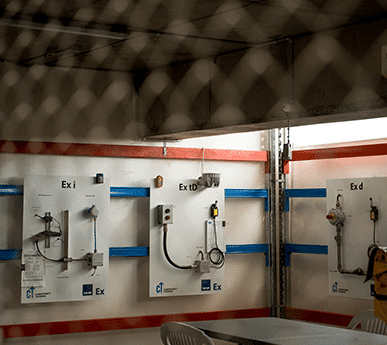

In terms of eruptive threat, a dangerous location is an environment in which an eruptive atmosphere exists (or might be expected to be present) in amounts that require special preventative measures for the construction, setup and use equipment. In this write-up we explore the obstacles dealt with in the office, the threat control steps, and the called for competencies to work safely.

(https://www.blogtalkradio.com/roarsolutions)

It is a consequence of modern-day life that we manufacture, save or handle an array of gases or liquids that are considered flammable, and a variety of dusts that are deemed flammable. hazardous area course. These compounds can, in particular problems, create explosive environments and these can have significant and awful effects. The majority of us are familiar with the fire triangular remove any type of among the 3 aspects and the fire can not occur, but what does this mean in the context of harmful locations? When damaging this down into its simplest terms it is basically: a mix of a certain amount of release or leak of a specific material or product, blending with ambient oxygen, and the visibility of a source of ignition.

This is then confirmed via evaluation and screening and is maintained throughout the life of the setup by utilizing the right upkeep techniques, supplemented by periodic assessment. When all these actions are taken, they should also be documented. The verification file consists of details such as the unsafe area classification drawing, producers' documents, equipment accreditation, style illustrations and estimations, examination documents, and records of an individual's expertise and proceeding expert advancement (CPD), such as by means of ECA's eCOMS software.

The Buzz on Roar Solutions

It is important that trainees comprehend and have a detailed expertise regarding what specifically comprises a hazardous location. The pupil needs to additionally recognize why training is essential prior to attempting to handle work or specifying equipment into a hazardous area. These locations are additionally called identified places and are defined as areas which have a high possibility of an explosion due to the feasible presence of combustible gases, vapors, dusts etc.

Industries that have unsafe locations are currently requiring that electrical workers that are specifying or working in these locations ought to have a dangerous area qualification that deems them qualified. Jobs in these sectors are really fulfilling so you need to be prepared. To satisfy this demand for the market, nationally recognised training in Certification IV in Dangerous location Electrical and EEHA training on the development of experienced specialists.

Getting The Roar Solutions To Work

Technology Abilities Australia is a Registered Training Organization offering you with the most budget-friendly and quickest method acquiring your qualification - hazardous area course. Our teachers are market qualified and have several years of procedure experience. Our programs have aided numerous people from company supervisors to day-to-day employees useful site in acquiring a solid hold on this not so complicated yet high threat training

The training additionally includes recognizing the harmful areas, resources of explosion and the residential properties of dangerous products together with the responsibilities and features of all parties, laws, systems, requirements and practice codes linked to hazardous locations. We provide instrumentation and unsafe area solutions that remain in conformity to most current AS/NZS and global industry criteria.

Report this page